Electric Gearbox Motor 12v

Motors need to be isolated from the AVR. This is because they

produce a high voltage spike when the current flow through them suddenly

changes. This can damage the digital circuitry in the microcontroller.

To separate the Gear-Box Motor from the microcontroller we used 4N35

optoisolators. Furthermore, ULN2003 drivers are used to supply the

motor's high current needs since the microcontroller has a maximum

current rating of 40mA. The drivers contain diodes to protect the

circuitry from high voltage spikes by directing the current through the

power supply.

The motor is controlled using an 8-step sequence to halve the rated

step angle. The step sequence rate is controlled via software. The 8

step sequence not only slows down the motor but also allows more

accurate positioning of the platform.

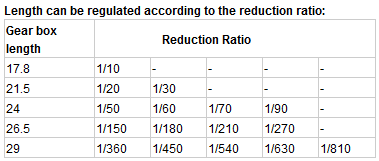

Electric gearbox motor, Speed reducer motor, Gear transmission motor

1) Diameter :37mm shaft: 6mm

2) 12v Custom made speed, Torque etc

|

| Assembling DC motor:(diameterxlength=35.8x57.0mm) |

|

| Geared motor installation: |

Appendix:

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

No comments:

Post a Comment