Etching Process

Wednesday, February 22, 2012

Wednesday, February 15, 2012

Week 5

PIC Fan controller

This project it´s based on a

PIC16F877A, with the purpose of control a FAN

with PWM (Pulse with Modulation). It offers a

variable speed control, low acoustic noise,

reliability, long lifetime, low power

consumption, protection features. The MCU get

the temperature from the sensor (D18B20), and

after will do a conversion Celsius degrees and

then it´s generated a PWM on PORTC.2 with 6

different levels.

|

PWM

|

TEMPERATURE

|

|

15%

|

<= 49°

|

|

30%

|

50° |

|

40%

|

51° |

|

50%

|

52° |

|

75%

|

53° |

|

100%

|

>54° |

After the signal goes to

Q1 (BC338) in order to control the duty cycle in

the fan. I had to use two transistors to have an

Ic on Q2 to be enough to activate the fan.

Because the MCU only generate a maxim of 3.6V on

which output, and 15% of 3.6V is 0.5V to

polarize Q1 we need 0.7V.

How to calculate

the Q1 and Q2:

You will be

able to control the FAN between 5V and

+/-12V.The BC338 have a current load of

800mA that is value of a fan can have, you

can use two or more fans as long the current

load isn´t more than 800mA. The output of

MCU connect to the Q1 and Q2 it works like a

switch, the D3 it´s for protection from the

magnetic field in the inductors from the

FAN, without the D3 when you turn off the

system the current will be discharge to the

Q2 and could damage it.

|

Connectors

|

|

|

J1 |

Expansions PORTS |

|

Source |

12V |

|

Sensor |

D18B20 |

|

FAN |

Connect the FAN |

|

ICSP |

To program with PICKIT2 |

Pictures:

Link

Thursday, February 9, 2012

Week 4

IR Receiver

|

| IR Receiver |

This is a simple IR receiver circuit which plugs into a serial port of a computer. There are many other circuits of this kind, and most of them are even simpler, but this circuit has two major advantages:

(1) it uses an Atmel AVR RISC microcontroller (an AT90S2313) instead of the usual PIC microcontroller

(2) it uses a Maxim MAX232 for the generation of valid RS232 levels.

Advantage 1: is, of course, only valid for all those AVR addicts which have this device (and the corresponding programmer) ready at hand and don't care about PICs and PIC programmers.

Advantage 2: comes into play if the IR receiver has to placed at a great distance from the computer. The MAX232 is more likely to deliver valid signals over bigger distances than cheaper solutions.

The IR receiver can receive it's +5V supply voltage from the keyboard or mouse connector of the computer (either from an unused PS/2 port or via a pass-thru adapter). If the IR interface is placed at a great distance from the computer, I power it with an external stabilized 5V DC power supply instead of the PS/2 port.

The interface communicates at 19200 baud, unidirectional (that means, it only transmits data and does not care anything about data which the computer send), without flow control. For every level transition in the demodulated IR signal, it transmits a single byte which corresponds to the time since the previous transition, capping off at a value of 255. It works reliable with a Sony remote control (using the special Sony protocol), and I have also successfully tested it with an Onkyo remote control (I think this one uses the standard RC5 protocol, but I'm not sure). Decoding happens on the computer; I use PC Remote Control for this.

Appendix:

|

| Infrared Receiver |

|

| Infrared Receiver to RF Transmitter Circuit |

|

| IR receiver sensor |

Link link2 link3 link4

Thursday, February 2, 2012

Week 3

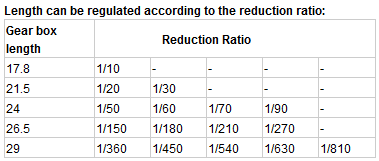

Electric Gearbox Motor 12v

Motors need to be isolated from the AVR. This is because they

produce a high voltage spike when the current flow through them suddenly

changes. This can damage the digital circuitry in the microcontroller.

To separate the Gear-Box Motor from the microcontroller we used 4N35

optoisolators. Furthermore, ULN2003 drivers are used to supply the

motor's high current needs since the microcontroller has a maximum

current rating of 40mA. The drivers contain diodes to protect the

circuitry from high voltage spikes by directing the current through the

power supply.

The motor is controlled using an 8-step sequence to halve the rated

step angle. The step sequence rate is controlled via software. The 8

step sequence not only slows down the motor but also allows more

accurate positioning of the platform.

Specifications:

1) Diameter :37mm shaft: 6mm

2) 12v Custom made speed, Torque etc

|

| Assembling DC motor:(diameterxlength=35.8x57.0mm) |

|

| Geared motor installation: |

Appendix:

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

Subscribe to:

Posts (Atom)